The equipment is used for multi-layer ceramic capacitor measuring and sorting, that is, multi-layer ceramic capacitors of different sizes and specifications are measured by special instrument CP/DF, and then the products with poor contact are detected and

| MLCC measuring and sorting content | |

|---|---|

| Items | Specifications |

| Applicable MlCC models | Applicable to 0402,0603,0805,1206;available for 1Mhz\1khz |

| Measuring cross head form | Monorail cross-head |

| Numbers of capacitance sorting grads | 5 |

| Meter model | Keysight Tech E4981A-001 |

| Measuring content | CP/DF |

| Test probe | Swipe type |

| Air pressure | 5kg/c㎡, with oil-water separator at the air intake |

| Power | 220V;10A |

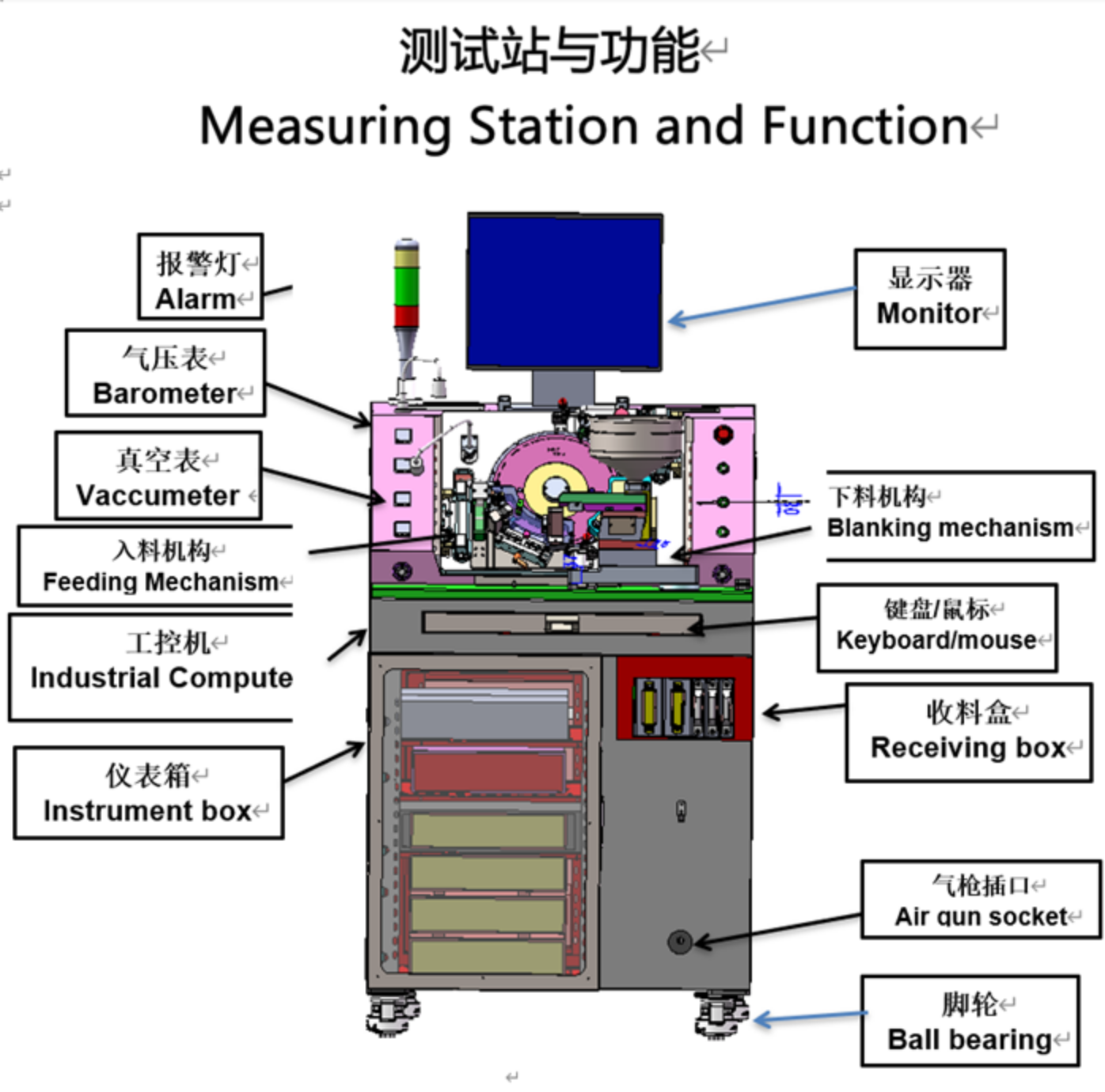

| Operations | Operated by button,keyboard and mouse |

| Controls | Industrial computer |

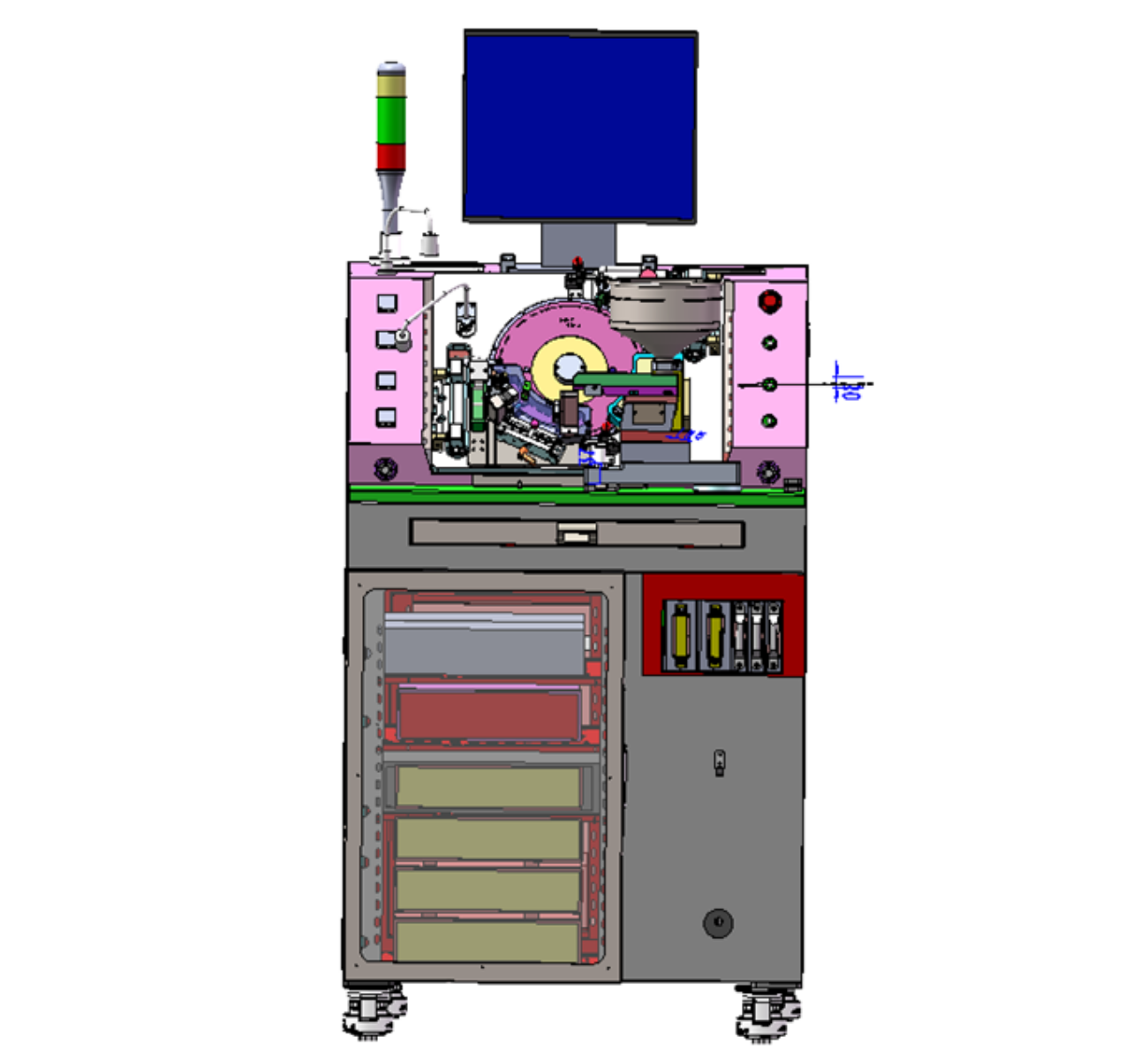

| Exterior Dimensions | L650mm* W700mm * H1147mm(Actual product may vary) |

| Weight | Approx. 70kg |

| Function Description impulse current measuring and sorting equipment | |

|---|---|

| Unit function | Description |

| operator interface | The operating interface is friendly to use; the working interface is free to switch; material is counted in real timeThe operating interface is friendly to use; the working interface is free to switch; material is counted in real timeThe operating interface is friendly to use; the working interface is free to switch; material is counted in real timeThe operating interface is friendly to use; the working interface is free to switch; material is counted in real timeThe operating interface is friendly to use; the working interface is free to switch; material is counted in real timeThe operating interface is friendly to use; the working interface is free to switch; material is counted in real time |

| Machine frame | The machine adopts method of metal plate welding; the nose adopts aluminium processing oxidation; the material box is convenient to pull; the equipment circuit |

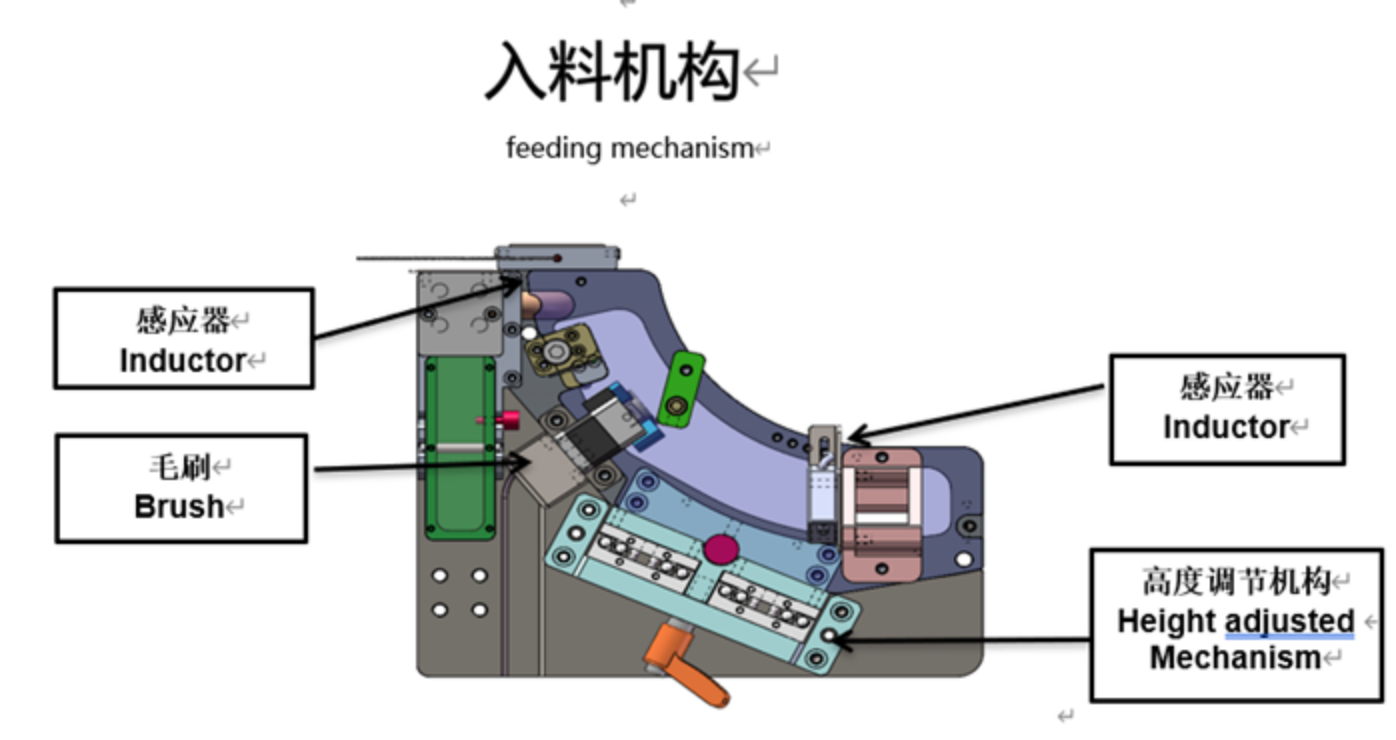

| cross-head mechanism | Hinge connection, open and close design; Line hiding without exposed, roller type test, large contact, accurate test; the roller is modular installation, |

| Charge and discharge | Use constant current and voltage test instrument |

| Test panel | Resin material, fine carving forming by machine, positioning pin installation, easy loading and unloading, convenient for replacement. |

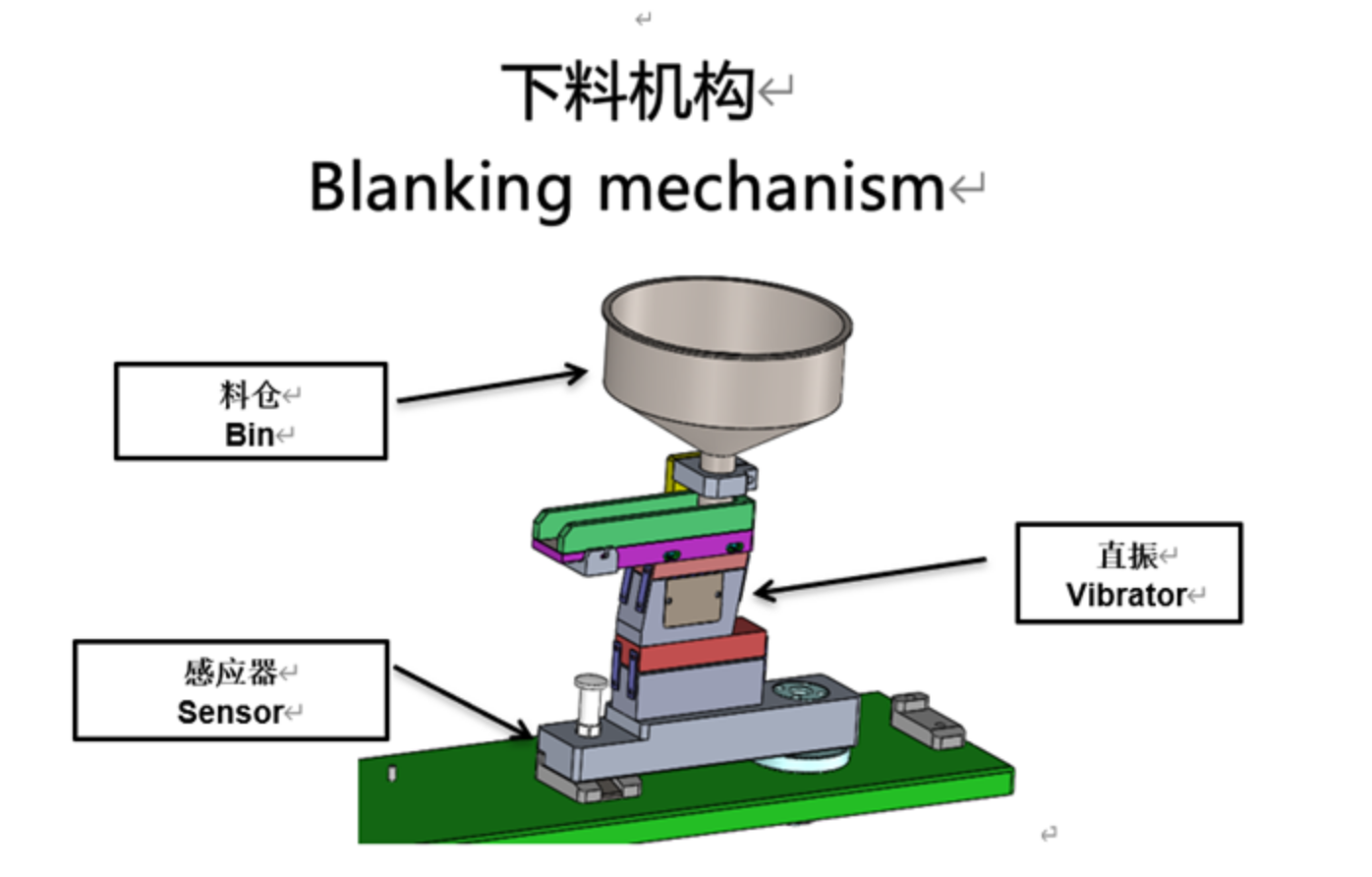

| Blanking mechanism | Induction type feeding, when the detection probe detects no material, the vibrator vibrates then feeding; vibrator can be adjusted manually by rotary knob. |

| Abnormal connection of instrument detection | Alarm if instrument is not installed or connected abnormally. |

back

back